The bend sensor is often used as an on-board sensor embedded on a performer / danser / comedian. It reacts to curving and bending, and can hence be attached inside an articulation such as the elbows, knees, or the foot's instep.

Full sensor : sensitive module + electronic card with settings

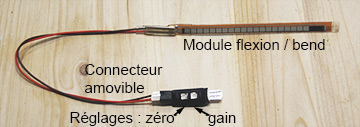

The sensitive module is connected to the sensor's electronic card with a 2 way connector.

This connector has an orientation key that can lightly keep the connection in place but lets it be detachable in case it is put under strain. This precaution prevents the wires from being torn or ripped off, or from breaking the sensitive module.

In case it gets detached, one can simply replug the connector onto the card.

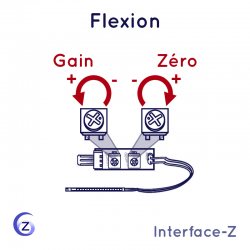

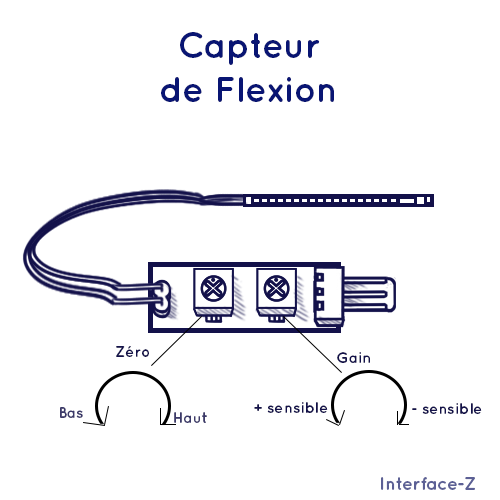

Our sensor is paired with electronics to denoise and adjust the measurement, which makes it stable and highly adaptable. Two potentiometers let one adapt this sensors to various uses that could require different sensitivities.

When combined, these two settings make our bendind sensor compatible to both light curving or very sharp bending.

The configuration procedure consists of :

This lets one have a full and optimal variation course, going from 0 to the maximum value in the protocol one is using (for example 127 is the maximum value in standard Midi), no matter the curvature one has planned for the module.

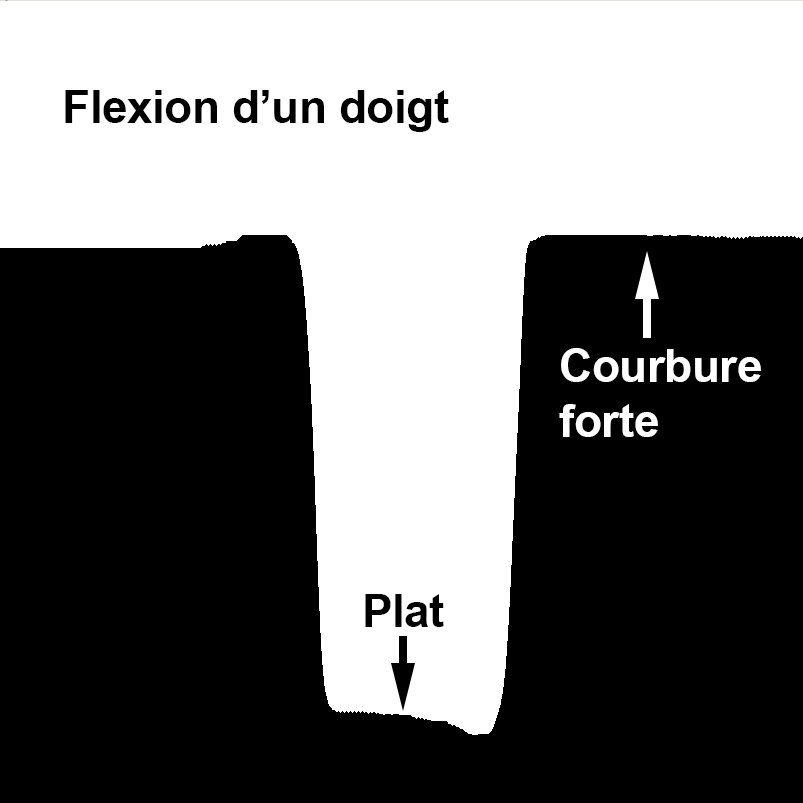

Data returned by the sensor over time

The sensitive part is fragile : one must not fold it completely (one can bend it into a circular curve but not fold and pinch it flat). It's also best to avoid making S shapes with it, and when embedded on the body do not use it on the interior par of the articulation (not in the knee-fold but rather over the kneecap, not in the elbowpits but rather along the length of the arm behind it).

The sensitive module is covered by a thin transparent sheathing, that protects the sensor but lets one see if it's damaged by checking the state of the little white square patterns on it.

![]()

Sensitive par of the sensor, covered by a sheath

This sensor can also be covered with a souple fabric sheathing. We currently do not sell one, but following below is a guide to making one by one's self.

This thin cover lets one easily position the sensor without damaging it : the folds in the fabric do not affect the sensitive module and the sheathing can then be sown/stuck/attached inside a costume.

Dimensions : 14 cm x 10,5 cm. The splint into which one can slide the bend sensor is sown in the middle of the sheath.

By making a hole at the tip of the transparent sheathing one can attach the module in place from a single point. The cover can then be rolled up to check the state of the sensor.

A perforation on the tip, to make it easier to stick in place.

Sheathing cover example to slide the sensor in properly.

Placing it in the cover.

Verifying the integrity of the sensor

Frédéric Braye made an interactive instrument that uses these bend sensors in particular.

One can listen to some of his creations here.

Noé Michaud and Mathilde Soliméo, AWAKENING (2016) :

Using a bend sensor to influence the music being produced.

Presentation of the artwork

In case they do get damaged, spare sensitive modules are sold on their own. They are made of the sensitive material, soldered to the necessary connectors in order to plug them onto the electronic card and into the protective sheathing.

They are directly usable with the little electronic card without any extra soldering (for the cards usually have the appropriate 2 pin connectors that just need to be plugged).

Il n'y a pas d'autres documents disponibles ici pour le moment.