Assembly:

Servomotors:

Brand: Interface-Z

Reference: act-8servo

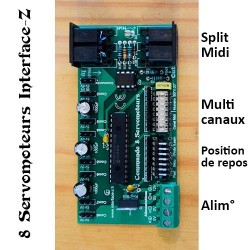

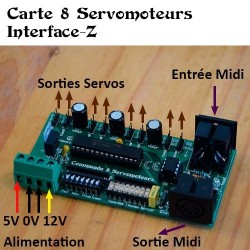

The 8 Servomotors Interface-Z board allows you to control up to 8 servomotors simply by sending them position commands in real-time. The board then ensures that each object stays in the chosen position until the next movement.

8 servo control board.

One single board is enough to control the motors with 128 positions (in standard Midi) or 3500 steps. These positions are distributed along the chosen range: 90° or 120° (or even 180°). This board also allows you to memorize rest positions and has a safety mode.

This demonstration video, created by Clément Payen, shows a small sound application with sticks striking cups and glasses. The programming was done in Max and uses the 8 Servos board in 128-step mode.

What is a servomotor? It’s a motor controlled in position. They are used to animate sculptures, robots, puppets, models, lighting, etc.

These motors rotate or place objects of varying weights (up to several kilograms) at a precise position. The most common ones allow positioning for a quarter or half-turn. Some rotate continuously at variable speed, others are servo-winches with multiple turns. The variety of adaptable heads, fixed on the axis, allows any object to be moved.

Servomotors can be found in modeling stores, but we can also supply them. The documentation shows how to connect them regardless of the brand.

For more details on servomotors, refer to the "Servomotor" page in the Tips section.

Our servomotor control boards are compatible with all types of classic motors: mini-servos, metal gears, winches, continuous rotation, etc. The only thing to check is the order of the wires – it is usually compatible with our boards, but there may be variations.

Objects fixed on servomotors can be:

- tools: sensors (rangefinders, cameras, optical systems, cameras, etc.) or control buttons (adjustment potentiometers for devices, adjustment sliders);

- or elements of sculptures or decor, contributing to the visual effect perceived by the public in the installation.

Examples of using servomotors.

By attaching sticks to the rotating head of the motors, you can create puppet animations, whose movements could be linked to music, the behavior of the audience, or even atmospheric conditions.

They are also used to block light projectors or video projectors completely or partially with perforated plates (thus enabling an absolute black effect).

They can also be used to orient objects, move lights, or small cameras.

Using modeling winches, you can tension wires to move fabrics or make objects rise and fall.

Coupling two servomotors allows you to orient an object in all three directions of space and thus create small robots.

Power Supply, Rest Position, Safety Mode, Interference... Some things to know.

You need to size the motors according to the weight they need to lift: a motor that's too weak will strain and risk breaking.

Motor Sizing

On the left, a motor that's too weak, straining; on the right, a motor that's powerful enough for this application.

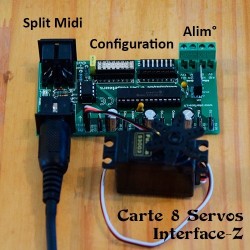

How to connect servomotors to the board, what power supply to use, and which software is compatible with the board?

Management of 8 servomotors

To be adaptable to anything, the 8 Servomotors module can be controlled from any software capable of sending Midi Control Change messages, such as: Max / MSP, Isadora, Usine, Pure-Data, Ableton Live, VVVV, EyesWeb, Processing, etc...

The channels and message numbers are configurable, which allows you to manage 8 boards (64 servomotors) per Midi channel and 16 channels, so a total of 512 servomotors.

Be careful not to reverse the connections to avoid damaging the motor. Markings on the board guide you in making the correct connections.

This short video shows the available wires on this type of power supply.

Power supply not included!

Standard servomotor range adjustable to 90° or 120°, in 128 steps or 3500 steps.

The board is controlled by activating switches on the board.

The position memory ensures that upon the next start of the board, the servomotors return to the chosen positions.

Safety mode ensures that, in the absence of Midi commands, the servomotors return to rest positions. For example, in case of a sudden shutdown of the computer controlling the motors, this prevents forcing, overheating, and damage.

The Midi output (marked Out) sends out the Midi messages received, allowing you to control another actuator board directly connected to the Servomotors board. This saves a Midi output port on the computer controlling the installation.

Be careful with running status in Midi.

Reminder: The partial kit only contains the printed circuit board and the programmed component. The rest of the components must be sourced separately.

Kit Assembly Help:

You can refer to the pages of help on component identification and markings: Nomenclature and description of electronic components

The current board is an evolution of older boards.

This board works exactly the same as the current one. The only difference is that it does not have the Midi split.

Documentation: 8-Servo-128-3500.pdf

Description pages remain online for users of previous versions. The current board is fully compatible with programs designed to work with the two older boards, but you must verify whether it is set to 128 or 3500 steps.

Older board

Documentation for older boards:

• Midi-SERVO 128 steps: Midi-Servo-128.pdf

• Midi-SERVO 3500 steps: Midi-Servo-3500.pdf

You might also like